The mold industry plays a pivotal role in modern manufacturing, serving as the backbone for producing high-precision components across various sectors, including automotive, aerospace, electronics, and consumer goods. As the demand for precision, efficiency, and customization grows, advanced technologies like laser marking and engraving machines have become indispensable tools in the mold-making process. This blog post explores the applications, benefits, and future potential of laser marking and engraving machines in the mold industry.

What Are Laser Marking and Engraving Machines?

Laser marking and engraving machines are advanced tools that use focused laser beams to etch, engrave, or mark surfaces with high precision. These machines are capable of working on a wide range of materials, including metals, plastics, ceramics, and composites. The process is non-contact, meaning there is no physical wear on the tool, and it offers unparalleled accuracy and consistency.

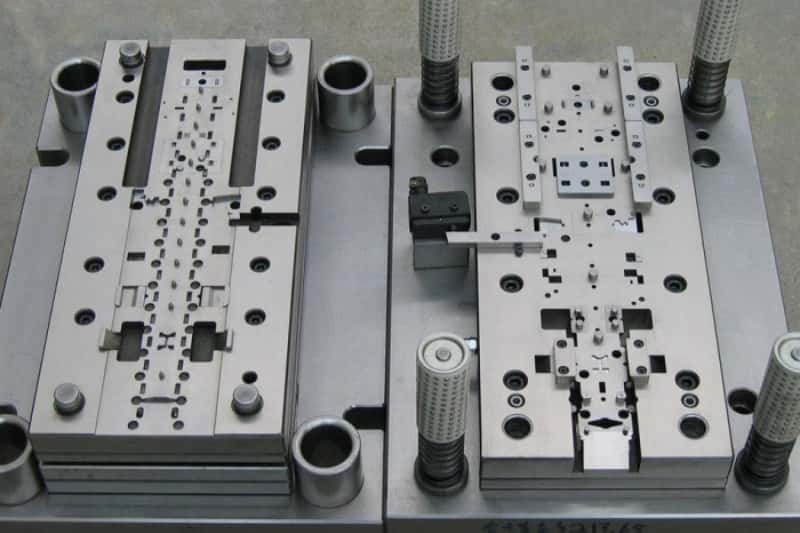

In the context of the mold industry, laser marking and engraving machines are used to create permanent markings, serial numbers, logos, and intricate designs on molds and their components. They are also employed for surface texturing, which can enhance the functionality and aesthetics of the final product.

Applications of Laser Marking and Engraving Machines in the Mold Industry

1. Permanent Marking and Identification

Molds often require permanent markings for identification, traceability, and quality control. Laser marking machines can engrave serial numbers, barcodes, QR codes, and other identifiers directly onto the mold surface. This ensures that each mold can be tracked throughout its lifecycle, from production to maintenance and eventual replacement.

2. Surface Texturing

Surface texturing is a critical process in mold making, as it directly affects the appearance and functionality of the final product. Laser engraving machines can create precise and consistent textures on mold surfaces, ranging from fine patterns to complex designs. This is particularly useful in industries like automotive and consumer electronics, where surface aesthetics are crucial.

3. Precision Engraving of Mold Cavities

Laser engraving machines excel at creating intricate details in mold cavities. This is especially important for molds used in injection molding, where the cavity design determines the shape and features of the final product. Laser technology allows for the creation of highly detailed and accurate cavities, reducing the need for manual finishing and improving overall efficiency.

4. Repair and Maintenance

Over time, molds can wear out or sustain damage, requiring repair or reconditioning. Laser engraving machines can be used to remove surface imperfections, restore textures, or re-engrave details, extending the lifespan of the mold and reducing replacement costs.

5. Customization and Prototyping

The mold industry often deals with custom orders and prototypes, where flexibility and speed are essential. Laser marking and engraving machines enable rapid customization of molds, allowing manufacturers to meet specific client requirements without significant delays.

Benefits of Laser Marking and Engraving Machines in the Mold Industry

1. High Precision and Accuracy

Laser technology offers micron-level precision, ensuring that even the most intricate designs and markings are executed flawlessly. This level of accuracy is critical in the mold industry, where even minor errors can lead to defective products.

2. Non-Contact Process

Unlike traditional engraving methods, laser marking and engraving are non-contact processes. This eliminates the risk of mechanical damage to the mold, preserving its integrity and extending its lifespan.

3. Versatility

Laser machines can work with a wide range of materials and shapes, making them suitable for various mold types and applications. Whether it’s a simple marking or a complex surface texture, laser technology can handle it with ease.

4. Speed and Efficiency

Laser marking and engraving are fast processes that can significantly reduce production times. This is particularly beneficial in high-volume manufacturing environments where time is of the essence.

5. Cost-Effectiveness

By reducing the need for manual labor, minimizing material waste, and extending mold lifespans, laser marking and engraving machines offer a cost-effective solution for mold manufacturers.

6. Environmentally Friendly

Laser processes are clean and produce minimal waste, making them an environmentally friendly option compared to traditional engraving methods that may involve chemicals or generate debris.

Future Trends and Innovations

As technology continues to evolve, laser marking and engraving machines are expected to become even more advanced and versatile. Some emerging trends in the field include:

- Integration with AI and Automation: The integration of artificial intelligence and automation will enable smarter and more efficient laser systems, capable of self-calibration, error detection, and real-time adjustments.

- Enhanced Material Compatibility: Ongoing research is focused on expanding the range of materials that can be processed using laser technology, including advanced composites and ceramics.

- 3D Laser Engraving: The development of 3D laser engraving systems will allow for more complex and detailed mold designs, opening up new possibilities for innovation in the mold industry.

- Green Laser Technology: The adoption of energy-efficient laser systems will reduce the environmental impact of mold manufacturing processes.

Conclusion

Laser marking and engraving machines have revolutionized the mold industry by offering unparalleled precision, efficiency, and versatility. From permanent marking and surface texturing to mold repair and customization, these machines have become essential tools for manufacturers looking to stay competitive in a rapidly evolving market. As technology continues to advance, the role of laser machines in the mold industry is only expected to grow, driving innovation and setting new standards for quality and efficiency.

For mold manufacturers, investing in laser marking and engraving technology is not just a step toward modernization—it’s a strategic move to ensure long-term success in an increasingly demanding industry. Whether you’re a small-scale workshop or a large-scale production facility, laser machines can help you achieve your goals with precision and ease.