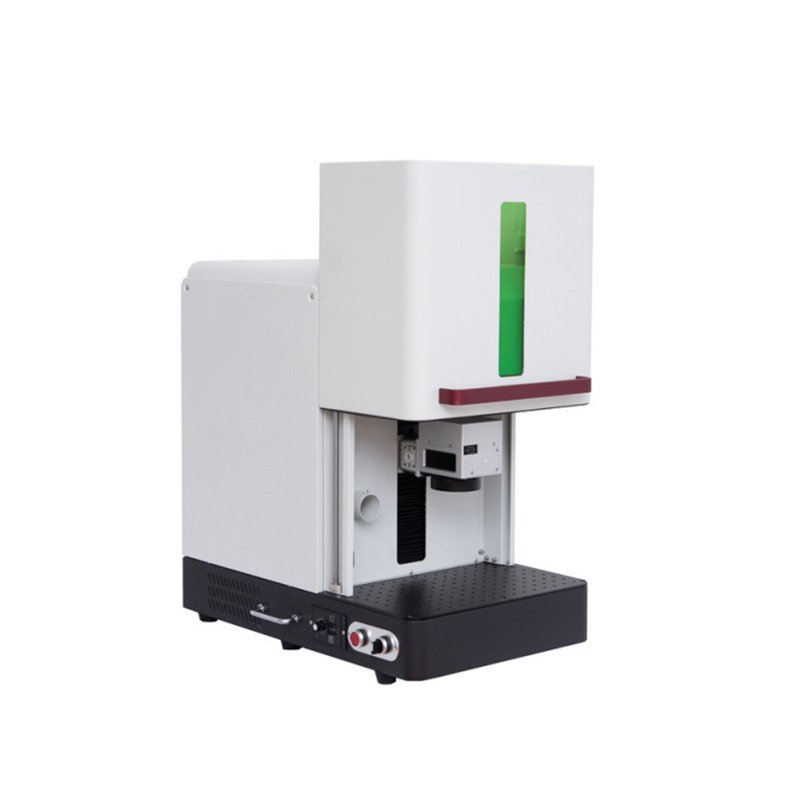

Description

Features

1. Energy, pulse width, frequency, and spot size can be adjusted over a wide range to achieve different welding effects. Parameter adjustments are made via a control rod inside a sealed chamber, making operation simple and efficient.

2. It uses an imported ceramic focusing cavity from the UK, which is corrosion-resistant, high-temperature resistant, and has a high photoelectric conversion efficiency. The focusing cavity has a lifespan of 8-10 years, while the xenon lamp lasts over 8 million flashes.

3. It employs a world-class automatic light-shielding system to eliminate eye strain from light exposure during operation.

4. Capable of continuous operation for 24 hours, it maintains stable performance and requires no maintenance for up to 10,000 hours.

5. Personalized design that conforms to ergonomic principles.

Application

This laser spot welder is specifically designed for gold and silver jewelry, golf balls, electronic component hole repair, welding sand holes, and welding inlays. It offers strong, aesthetically pleasing, non-deforming welds, is easy to operate, and convenient to use.

Parameter Sheet

[table id=12 /]