As a leader in industrial laser technology, Synmark Laser offers advanced solutions for the auto parts laser marking machine sector. In the highly competitive and regulated automotive industry, the ability to ensure traceability, quality, and brand integrity is paramount. Laser marking technology provides a robust and permanent method for direct part marking (DPM) on a vast array of materials, from metals to plastics. This article explores the comprehensive applications of laser marking machines in the automotive parts manufacturing process, detailing their role in enhancing supply chain visibility, ensuring compliance with international standards, and improving production efficiency. From high-stress engine components to intricate interior electronics, laser marking is the modern standard for permanent and precise part identification.

The Power of Precision: Auto Parts Laser Marking with Synmark Laser

The automotive industry, a complex global network of manufacturers, suppliers, and distributors, demands unparalleled precision and reliability at every stage. For modern vehicle production, a component’s identity is as critical as its function. This is where the auto parts laser marking machine becomes an indispensable asset. At Synmark Laser, we understand the unique challenges of this sector, providing laser marking solutions that meet and exceed the industry’s stringent requirements for durability, speed, and accuracy.

The Indispensable Role of Laser Marking in Automotive Manufacturing

Traditional marking methods, such as inkjet printing, stamping, or labels, often fail to meet the harsh demands of the automotive environment. These marks can fade, smudge, or peel off due to exposure to high temperatures, engine oils, vibrations, and other chemicals. In contrast, laser marking creates a permanent, high-contrast mark by altering the material’s surface at a molecular level. This ensures that critical information remains legible throughout a part’s entire lifecycle, from the assembly line to the scrapyard.

The primary driver for implementing laser marking technology is traceability. Every component, from a simple bolt to a complex electronic control unit, must be traceable to its origin. This is crucial for:

- Quality Control and Recalls: In the event of a manufacturing defect, a permanent mark allows manufacturers to quickly identify and recall only the affected batch, minimizing costs and brand damage.

- Supply Chain Management: With millions of parts moving across global supply chains, laser-marked codes (such as 2D data matrix codes and QR codes) enable real-time tracking, optimizing inventory management and logistics.

- Anti-Counterfeiting: Permanent, intricate laser marks serve as a powerful deterrent against counterfeit parts, which pose significant safety risks and financial losses to both consumers and manufacturers.

Comprehensive Applications Across Automotive Components

Synmark Laser’s technology is versatile enough to be deployed across the entire spectrum of automotive parts. Here are some of the most critical application scenarios:

1. Engine and Powertrain Components

These components operate under extreme conditions of heat, pressure, and friction, making permanent marking essential.

- Pistons, Connecting Rods, and Crankshafts: Marking of serial numbers, production dates, and batch codes on metal surfaces to ensure traceability and quality assurance.

- Engine Blocks and Cylinder Heads: Deep laser engraving of Vehicle Identification Numbers (VINs) and engine codes for permanent, anti-theft identification.

- Bearings and Gears: High-speed laser marking of part numbers and manufacturer logos for quality control and brand authentication.

2. Chassis and Structural Parts

For a vehicle’s structural integrity, precise and durable marking is non-negotiable.

- Brake Systems: Marking of part numbers on brake discs, calipers, and pads. The marks must withstand high-temperatures and brake dust abrasion.

- Suspension and Steering Components: Application of QR codes and serial numbers on struts, control arms, and steering knuckles to track their manufacturing and assembly history.

- Exhaust Systems: Marking of materials that endure extreme heat and corrosive gases, such as catalytic converters and exhaust pipes.

3. Automotive Electronics and Sensors

With the rise of electric vehicles and autonomous driving, the number of electronic components is soaring. Laser marking provides a non-contact, damage-free method for marking sensitive materials.

- Electronic Control Units (ECUs): Marking of delicate circuit boards and plastic housings with serial numbers and compliance codes.

- Sensors and Actuators: Micro-marking of part numbers on small, complex sensor housings for airbag systems, tire pressure monitoring systems (TPMS), and engine management.

- Battery Cells and Packs (for EVs): Marking of unique identifiers on individual battery cells to track their performance, origin, and for end-of-life recycling management.

4. Interior and Exterior Parts

Laser marking is also used for both functional and aesthetic purposes on visible components.

- Dashboard and Control Buttons: Creating backlit buttons by selectively removing layers of paint, allowing light to shine through. This application is both precise and durable.

- Instrument Panels and Trim Pieces: Marking of batch codes and material information for quality assurance and to facilitate material recycling.

- Headlights and Tail Lights: Marking of E-mark and DOT compliance symbols on polycarbonate and glass surfaces.

5. Other Specialized Applications

- Keys and Locks: Permanent engraving of key codes and security features.

- Labels and Nameplates: High-speed marking of metal or plastic tags used for component identification.

- Rubber and Plastic Seals: Marking of logos and material codes on rubber seals and gaskets without damaging their integrity.

The Synmark Laser Advantage

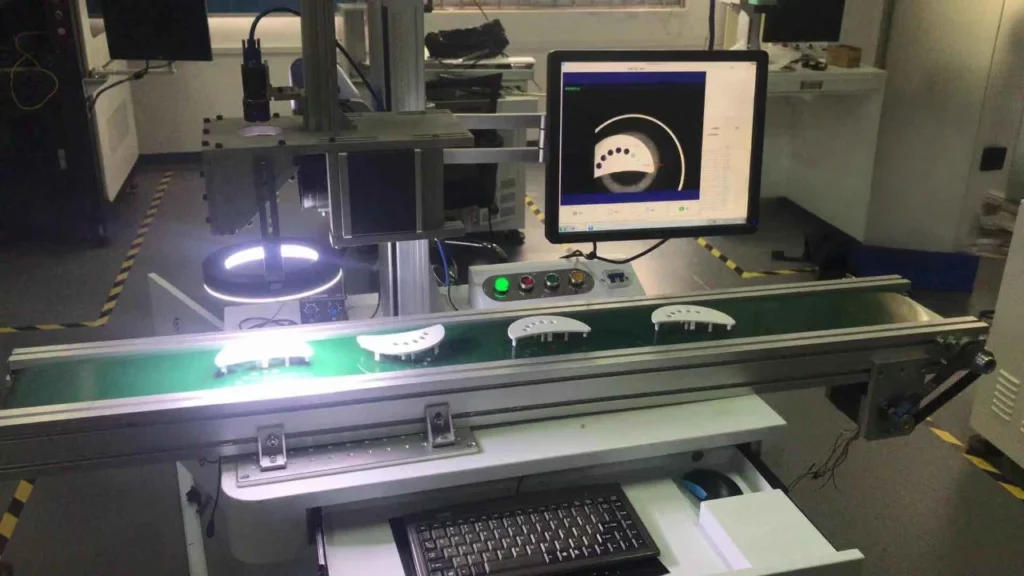

Synmark Laser’s auto parts laser marking machine solutions are engineered to integrate seamlessly into modern automated production lines. Our systems offer:

- Superior Speed and Efficiency: Our advanced galvo scanning technology allows for high-speed marking, keeping pace with high-volume production cycles.

- Versatility: Our systems can mark a wide range of materials, including various metals (steel, aluminum, titanium), plastics, ceramics, and composites, using different laser types (e.g., fiber, CO2, UV).

- Unrivaled Precision: Our lasers produce incredibly fine, high-resolution marks, even on curved or irregularly shaped surfaces.

- Robust and Low-Maintenance Design: Built for the demanding factory environment, our machines require minimal consumables and offer long-term reliability.

The adoption of laser marking technology is not just a trend; it’s a strategic imperative for any company in the automotive sector committed to quality, safety, and operational excellence. At Synmark Laser, we are dedicated to providing the tools that drive this future.