Product Features

High Precision Marking: The ultraviolet laser has a short wavelength and a small focused spot, making it suitable for ultra-fine marking with high resolution.

Cold Processing Technology: The ultraviolet laser has a small thermal impact on materials, making it suitable for heat-sensitive materials.

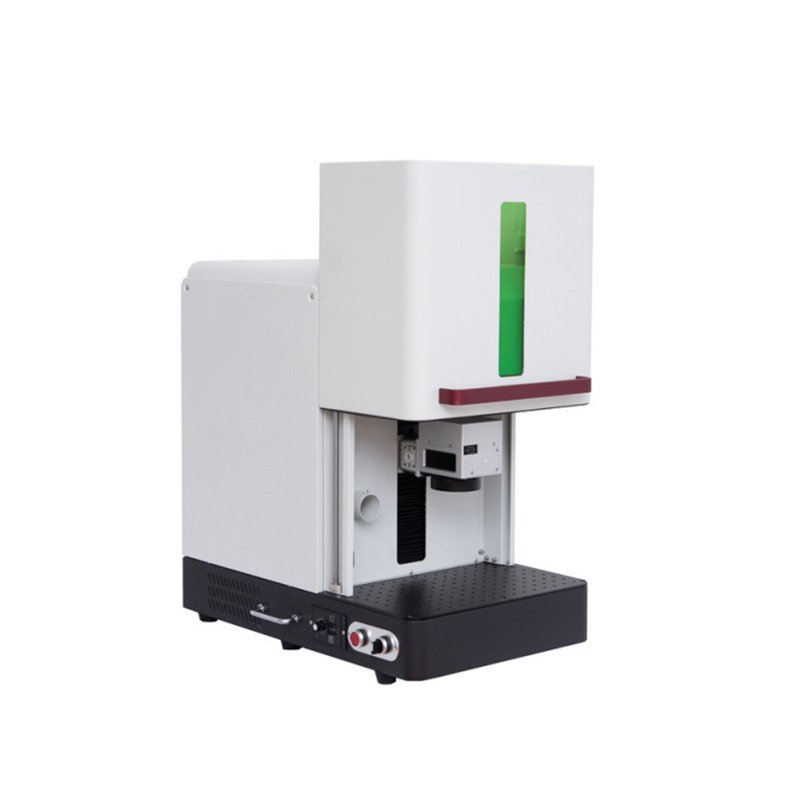

Air Cooling Design: No need for an external water cooling system. Compact structure and convenient maintenance.

Non-contact Processing: No physical contact required, avoiding material deformation or damage.

Multifunctionality: Supports various marking contents such as text, patterns, QR codes, barcodes, and serial numbers.

Efficient and Stable: Fast marking speed, stable performance, suitable for batch production.

Simple Operation: User-friendly interface, supports quick setting and parameter adjustment.

Long-Lived Laser Source: The ultraviolet laser source has a long lifespan and low maintenance costs.

Environmentally Friendly and Energy-Efficient: No consumables, no pollution, low energy consumption.

Applicable Materials

Plastics: Including various types of plastics such as PVC, PC, ABS, PP, PE, polystyrene (PS), polylactic acid (PLA), acrylic (PMMA), acetal (polymethyl acetal, POM), nylon (PA), etc. The ultraviolet laser can induce photochemical reactions on their surfaces, resulting in clear and durable marks.

Glass and Crystal: Suitable for mobile phone screens, LCD screens, optical devices, automotive glass, crystal products, etc. Non-contact marking can be carried out to create high-precision and high-definition patterns and texts without damaging the material surface.

Ceramics: Whether it is unglazed ceramics or glazed ceramics, ultraviolet laser can be used for clear and permanent marking.

Silicon Materials: In the semiconductor industry, it is often used for high-precision marking and cutting on silicon materials such as silicon wafers and wafers.

Metals: Such as stainless steel, aluminum, gold, platinum, silver, titanium, brass, etc. Visible and durable marks can be produced on the surfaces of metal materials, but the marking effect may not be as obvious as that of fiber laser marking machines.

Rubber and Leather: Fine patterns and texts can be created on rubber and leather materials.

Wood Materials: Including mahogany, walnut, oak, birch, and various other woods as well as medium-density fiberboard, plywood, and fiberboard, etc., all can be engraved and marked.

Packaging Materials: Commonly used in packaging materials for industries such as food and medicine, such as plastic bottles, glass bottles, aluminum foil, etc., for non-contact and pollution-free marking.

Application Scenarios

Electronic Industry: Used for marking and coding of electronic components such as chips, resistors, capacitors, etc.; it can also be used for marking, slicing of flexible PCB boards, and QR code marking on LCD glass, etc.

Semiconductor Industry: Conduct high-precision marking, cutting, and micro-hole processing on semiconductor materials such as silicon wafers and wafers, meeting the fine processing requirements in semiconductor manufacturing processes.

Medical Industry: Mark on medical devices, drug packaging, test kits, etc., obtaining permanent identification marks that are resistant to sterilization and disinfection, meeting the FDA and MDR standards of the medical industry.

Food and Beverage Industry: Mark on food packaging, beverage bottles, etc., with production dates, shelf life, batch numbers, QR codes, etc., featuring clarity, firmness, and no pollution, meeting the requirements of food hygiene and safety.

Cosmetics and Personal Care Industry: Mark on cosmetic packaging, plastic bottles, glass bottles, etc., with brand identification, specification descriptions, production dates, etc., enhancing the appearance quality and brand image of the products.

Aerospace Industry: Can be used for marking of insulation layers of wires and cables in aerospace fields, as well as high-precision marking of some components, meeting the high-quality and reliability requirements of aerospace products.

Crafts Industry: Carve and mark on glass, crystal, ceramics, wood, etc., creating exquisite patterns and texts, increasing the artistic value and ornamental appeal of the crafts.

Packaging Printing Industry: Mark and code various packaging materials to achieve clear and accurate identification of product information, and also be used for the production of anti-counterfeiting marks for packaging materials.