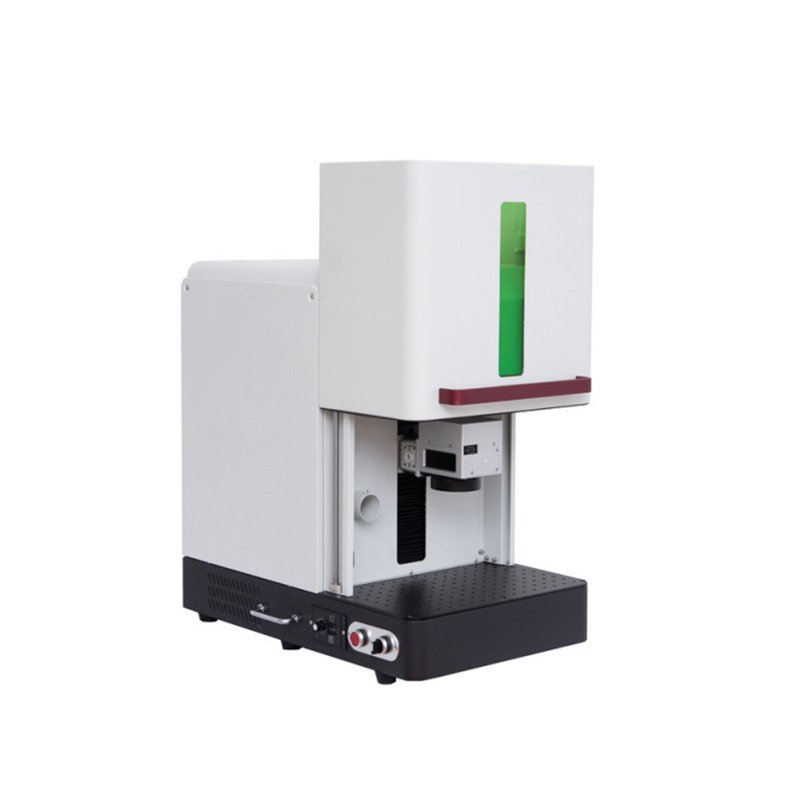

Features:

1. Plug-in mode, charging mode, and battery swap mode. Built-in battery of 11600mA, replaceable lithium battery, standby time up to 12 hours.

2. Industrial-grade high-strength ABS plastic one-piece molded housing.

3. Robust screen protection layer, shock-resistant and scratch-resistant.

4. Touchscreen operation, simple and fast, easy for beginners to use.

5. Multiple marking modes, supporting various vector graphics such as PLT, JPG, DXF, BMP, as well as text engraving, automatic barcode, and automatic QR code marking.

6. Compact size, more convenient to carry.

Applicable Materials

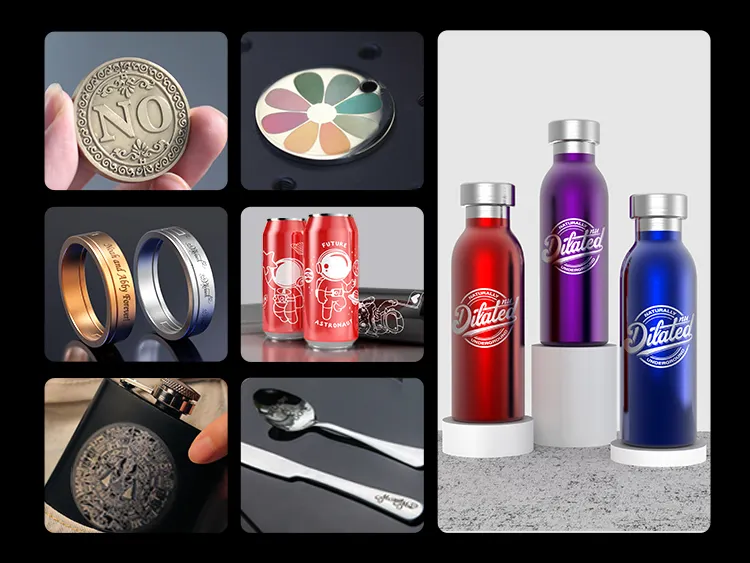

1. Metal Materials

The marking effect of fiber laser marking machines on metal materials is excellent and is suitable for the following common metals:

Stainless steel: used in medical devices, industrial parts, kitchenware, etc.

Aluminum and aluminum alloys: used in electronic product casings, automotive parts, aerospace components, etc.

Copper and copper alloys: used in electronic components, electrical equipment, circuit boards, etc.

Titanium and titanium alloys: used in aerospace components, medical devices, high-end consumer goods, etc.

Zinc, magnesium, nickel: used in special industrial applications, such as battery casings, precision parts, etc.

Gold, silver: used in jewelry, luxury goods, etc. for fine marking.

Iron and carbon steel: used in tools, molds, mechanical parts, etc.

2. Non-metal Materials

Although fiber laser marking machines are mainly used for metal materials, they can also achieve good marking effects on some non-metal materials:

Plastics: suitable for some plastic materials such as ABS, PC, PP, etc., commonly used in electronic device casings, packaging materials, etc.

Coated materials: such as anodized aluminum, sprayed surfaces, etc.

Ceramics: used in industrial ceramics, decorative items, etc.

3. Composite Materials

Carbon fiber composite materials: used in aerospace, automotive industry, etc. for high-strength components.

Marking effect on applicable materials

Metal materials: clear and permanent marking effect, suitable for high-precision identification.

Non-metal materials: the effect varies depending on the material, and laser parameters may need to be adjusted for some materials.

Coated materials: a distinct marking effect can be achieved by removing the surface coating.

Summary

Fiber laser marking machines are mainly suitable for metal materials such as stainless steel, aluminum, copper, titanium, etc., and can also achieve good marking effects on some non-metal materials (such as plastics, coated materials) and composite materials. Their high precision and high efficiency make them an ideal choice in the field of industrial marking.

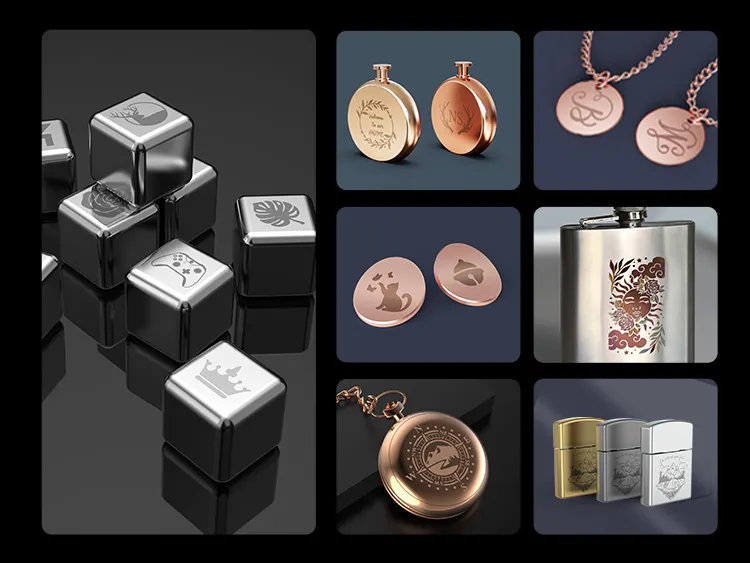

Industry Applications

Electronic Industry: Used for marking and coding of electronic components such as chips, resistors, capacitors, etc.; it can also be used for marking, slicing of flexible PCB boards, and QR code marking on LCD glass, etc.

Semiconductor Industry: Conduct high-precision marking, cutting, and micro-hole processing on semiconductor materials such as silicon wafers and wafers, meeting the fine processing requirements in semiconductor manufacturing processes.

Medical Industry: Mark on medical devices, drug packaging, test kits, etc., obtaining permanent identification marks that are resistant to sterilization and disinfection, meeting the FDA and MDR standards of the medical industry.

Food and Beverage Industry: Mark on food packaging, beverage bottles, etc., with production dates, shelf life, batch numbers, QR codes, etc., featuring clear, firm, and pollution-free characteristics, meeting the requirements of food hygiene and safety.

Cosmetics and Personal Care Industry: Mark on cosmetic packaging, plastic bottles, glass bottles, etc., with brand identification, specifications, production dates, etc., enhancing the appearance quality and brand image of the products.

Aerospace Industry: Can be used for marking of insulation layers of wires and cables in aerospace fields, as well as high-precision marking of some components, meeting the high-quality and reliability requirements of aerospace products.

Crafts Industry: Carve and mark on glass, crystal, ceramics, wood, etc., creating exquisite patterns and characters, increasing the artistic value and ornamental appeal of the crafts.

Packaging Printing Industry: Mark and code various packaging materials to achieve clear and accurate identification of product information, and also be used for the production of anti-counterfeiting marks for packaging materials.