Get in tech: 0086 158 0666 7020

Online message: Click here

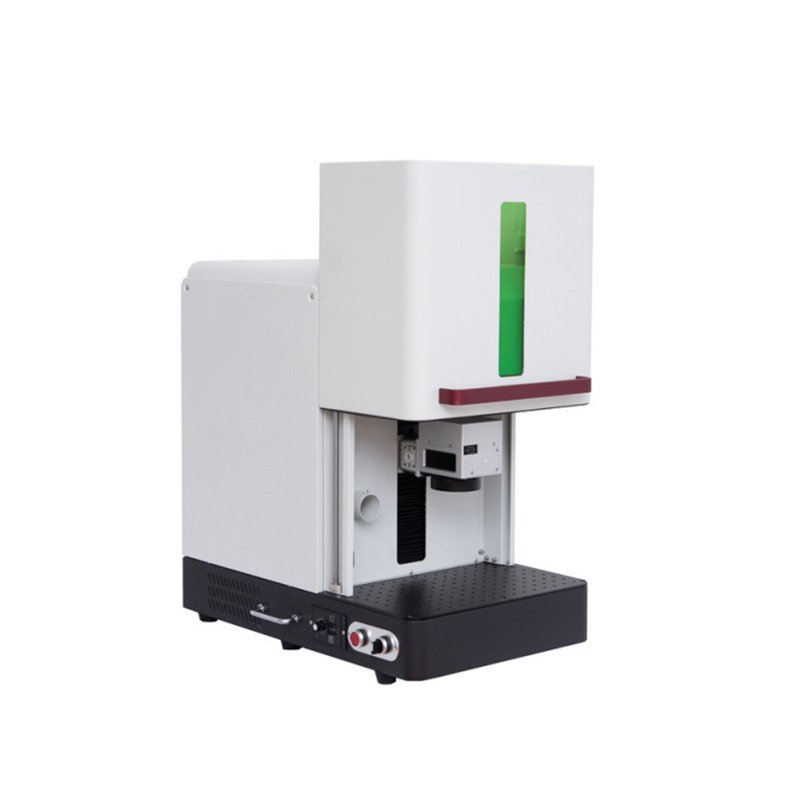

Features of the Fiber Laser Marking Machine

- Exceptional Precision: Provides precision up to 0.0012mm, ensuring outstanding and satisfactory marking quality.

- Advanced Laser Beam: Offers a definition of 1 micron, which is ten times greater than that of conventional products.

- No Need for Consumables: A single fiber marker can function for over 10 years without requiring any consumables.

- Rapid Operation: Capable of marking at a speed of 800 standard characters per second, which is 3 to 5 times faster than traditional models.

- Direct Fiber Laser Output: The fiber laser beam comes directly from the IPG fiber device, which eliminates the necessity of adjusting the laser optical path.

- Low Energy Consumption: Operates at less than 400W, making it more cost-effective and environmentally friendly.

- Stable Control System: Features a reliable Scaps controller with high stability, a USB interface for quick and secure data transmission, route optimization, intelligent calculation, and user-friendly operation.

- High-Performance Scan Head: The original ScanLAB scan head delivers high speed and accuracy, has a good seal to protect against dust and water, and is compact in design.

- Long Operational Life: The IPG laser module lasts between 100,000 and 200,000 hours.

- Wide Compatibility: Supports numerous file formats such as TTF Font, SHX, BMP, DXF, AI, PLT, and is compatible with software like CorelDraw, Photoshop, AutoCAD, and Solidworks.

- Efficient Air Cooling System: Provides better cooling performance compared to water cooling in YAG lasers and requires no maintenance.

Applications of the Fiber Laser Marking Machine

- Electronic Components: Used for marking items such as resistors, capacitors, chips, printed circuit boards, and computer keyboards.

- Mechanical Parts: Suitable for marking mechanical components like bearings, gears, standard parts, and motors.

- Instruments: Ideal for marking panel boards, nameplates, and precision equipment.

- Hardware Tools: Applicable for knives, tools, measuring instruments, and cutting tools.

- Automobile Parts: Useful for marking pistons and rings, gears, shafts, bearings, clutches, lights, and other automotive components.

- Daily Necessities: Can mark various everyday items including handicrafts, zippers, key holders, and sanitary ware.

Parameters of the Fiber Laser Marking Machine

[table id=4 /]

Payment and Delivery

[table id=1 /]